Supply chain managers face many challenges, including growing demand for end-to-end sustainability. Continue reading for key methods to leverage technology to boost your supply chain sustainability.

Already, businesses in the Asia-Pacific region are at the forefront of supply chain innovation, employing new technological and managerial strategies to improve sustainability. The right interventions allow companies to significantly improve the environmental impact of their logistics operations and adopt more eco-conscious plans.

Enterprise Resource Planning

Many modern enterprise resource planning (ERP) tools are built with management for environmental, social and governance (ESG) criteria, which are increasing in importance in the supply chain. They are often powerful tools for helping executives measure and manage the environmental impact of a business’ operations.

The right solution may even automatically calculate the potential carbon footprint of product development and logistical decisions. This helps executives plan changes to the supply chain concerning the potential environmental impact.

For example, executives could use estimates of the logistics operations’ fuel consumption to determine how much emissions are generated across a business’s supply chain. They can then see how interventions like alternative fuel vehicles, efficiency upgrades or fleet electrification may impact the company’s carbon footprint.

Executives can use these numbers to weigh cost versus environmental benefit more effectively when making supply chain decisions. This takes some of the uncertainty out of logistics decision-making that prioritises sustainability.

Real-Time Asset Tracking

Businesses often face greater pressure to provide faster deliveries with less lead time as customer expectations rise. However, accelerating delivery can be a challenge if companies can’t effectively track and predict the movement of goods, especially overseas or internationally. Prioritising delivery time without sacrificing sustainability can also be difficult. Managers may feel forced to choose the fastest delivery options and carriers at the expense of slower, more eco-friendly shipping options.

A combination of fleet and asset tracking tools, which rely on technologies like RFID or GPS, can help businesses keep better track of goods in transit. This makes it easier to provide detailed shipping information to clients and more accurately predict delivery timing. Better information allows executives to prioritise sustainable decision-making in the supply chain.

Tracking can also help businesses ensure goods are transported in the right condition. For example, Internet of Things (IoT) temperature monitors can track the environmental conditions produce is shipped in. Tiny fitness trackers can check lobsters for movement while they are in transit.

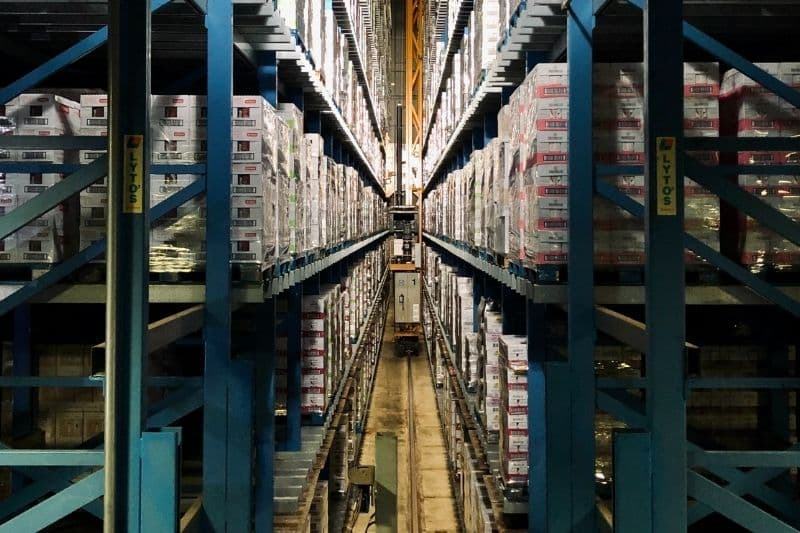

These tools can also make improving supply chain sustainability much easier. Effective capacity planning uses real-time data on the location of goods and assets. This lets businesses avoid the underutilisation of resource-intensive assets, including vehicles and storage space. Maximising asset utilisation makes it possible to reduce the overall carbon footprint.

Fleet Management Software

Fleet tracking data, combined with telematics systems that provide real-time information on vehicle performance and management software, can allow managers to more effectively monitor drivers and trucks. This allows for process and policy changes that improve efficiency.

For example, this technology can help fleet managers identify and mitigate driver behaviours that increase vehicle fuel consumption. This includes exceeding posted speed limits, idling, rapid starting and stopping, and using air conditioning at lower speeds.

Managers can also use fleet management software to identify inefficient and underutilised vehicles. They can spot fuel-inefficient trucks more easily, allowing them to target upgrades that will provide the greatest environmental benefits.

Additive Manufacturing

Additive manufacturing, also called 3D printing, does more than improve lead times and enable the cheap production of small-batch runs. These techniques can also help make supply chain operations significantly more sustainable.

In practice, this technology can help shorten supply chains by moving manufacturing operations closer to clients, customers, or other points of need.

The right additive manufacturing capabilities in the right place can potentially eliminate the need for entire links in the supply chain. It can shift operations overseas to the same country or landmass as a client, accelerating deliveries and eliminating emissions at the same time.

Leveraging New Technology

The right technology can help APAC businesses make their supply chain more sustainable. New management and planning solutions, smart tracking technology, and additive manufacturing have the potential to make logistics operations much more eco-friendly.

Executives and logistics managers can leverage these technologies to improve supply chain decision-making and ensure operations are in line with ESG criteria. This can provide the boost in sustainability needed to compete in today’s competitive and eco-minded marketplace.

Related Articles

The Digital Evolution of Logistics