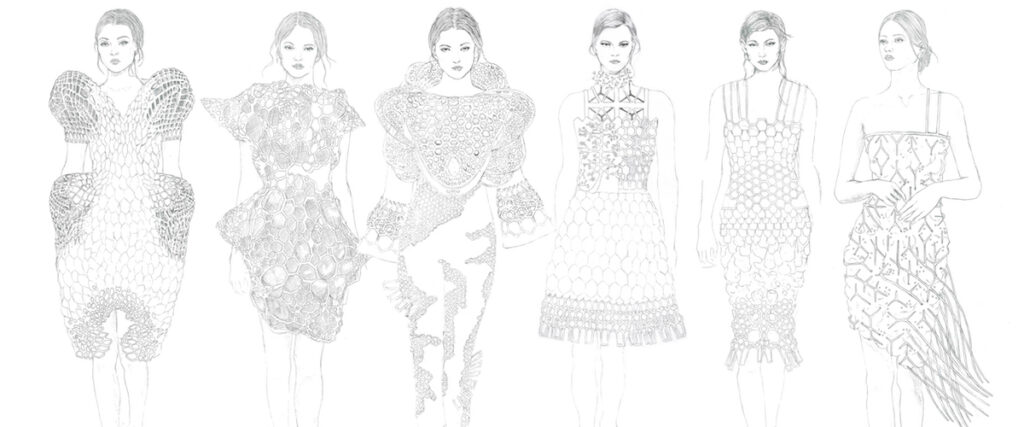

Creating her pieces wholly from a 3D printer, Jamela Law has meticulously designed, printed and built looks after looks to create her Beeing Human collection.

3D fashion is still relatively new to the Singaporean market. We’d love to be educated.

We wanted Baëlf to be a trend-leader in the burgeoning 3D printed fashion industry with Singapore as a starting point. 3D printing removes barriers to resources and skills that had previously prevented generations of designers from realizing their ideas. We can now easily explore intricate forms and futuristic silhouettes by playing with complex mathematical formulas and novel geometries. Additionally, our garments are designed, personalized and manufactured in conjunction with complementary technologies such as 3D scanning.

Can you share more on the process of creating a 3D collection?

We employed a myriad of different techniques to create this collection. Some parts are 3D printed using a Selective Laser Sintering process in nylon material, some in elastomer (a rubber like flexible material) and some using common biodegradable PLA filaments. We have also 3D printed resin molds to cast parts of the designs in silicone. Using these processes allows us to create parts ‘to order’, building only what we need instead of relying on costly, consumption-heavy mass production methods.

We also want to bring into awareness that these new technologies could be a sustainable alternative to conventional sweatshop practices and large scale industrial wastage. Not all plastics are harmful to the environment as long as one recycles them correctly. We used a biodegradable 3D printing filament called BioFila Silk that is based on lignin, which is derived from wood to build some of my elements. Not only is it a renewable raw material, it has a higher hardness value which makes it more durable.

Now think, if silk could be printed aesthetically, we could stop boiling silkworms alive just for the sake of obtaining that perfect, long strand and use choppy, ethically obtained leftover ones instead.

What are your future plans?

For every new work, we wish to explore limits of fabrication process and find ways to achieve breakthroughs. We are currently preparing to launch our bio-mimicry inspired accessories at Art Science Museum in collaboration with Fab Café. Come October, we will also be exhibiting in a couple of shows in San Francisco. Please follow us on Instagram @baelf_design to get more updates!

Related Articles

5 Entrepreneurial Tips to Get Your Fashion Business Started