Miniwiz is the Taiwan-based upcycling powerhouse that has transformed the world’s waste into over 1,200 new materials for the building of a zero-carbon, close-loop society. And that’s just one of their projects.

When you look at your rubbish bin, what do you see? Filthy bits of trash? For Taiwanese upcycling pioneers Miniwiz, that rubbish is as valuable a resource as oil or coal – worth more than USD 100million, to be precise. The closed-loop trash application company, as its CTO Javis Liu describes it, collects consumer and industrial leftover waste – everything from cigarette butts to electronic waste and plastic bottles – and transforms it into cool gadgets, building blocks, alternative packaging and more. Headquartered in Taiwan, Miniwiz has been crusading against waste around the globe since 2005 with their pioneering upcycling technology. Under the leadership of structural engineer Jarvis and architect Arthur Huang, who live by the motto ‘It is wise to minimize’, Miniwiz is on a mission to forge a future in which rubbish is anything but.

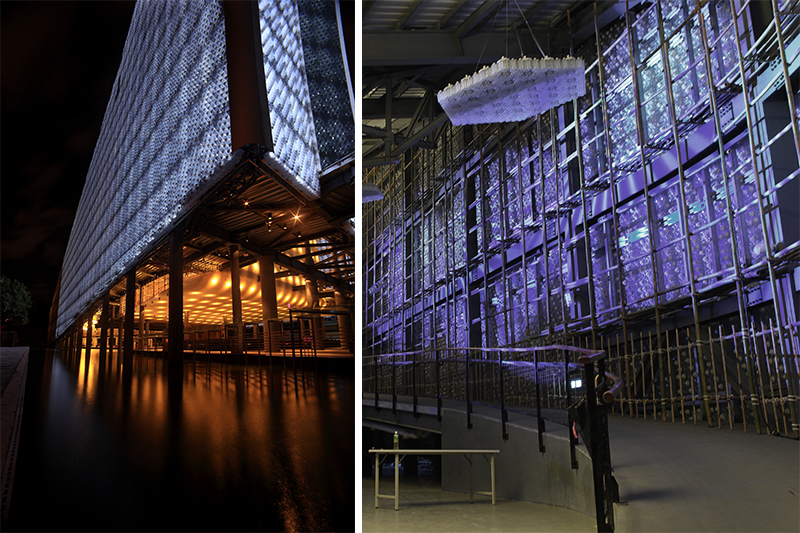

Sitting a room away from Miniwiz’s laboratory dubbed ‘the trash lab’ in downtown Taipei, Javis Liu lays before him a ‘polli-brick’, the very same hollow building block that was used to construct the EcoArk pavilion, a nine-storey exhibition hall located in the heart of Taipei city. The lightweight upcycled product is manufactured through the shredding, melting, compressing, and reshaping of 1.5 million recycled polymer plastic bottles. “For the past 10 years, we have experimented on over 800 different waste materials to understand their mechanical properties. These bricks are one success out of countless trials and errors,” says Javis, laughing.

Growing up in Taiwan, it never occurred to Javis that he would want to spend his youthful years in a lab working through rubbish. But the turning point came when he majored in architecture in Tunghai University in Taiwan. “As architects, we exploit raw materials to create new buildings, but what comes with that is the staggering amount of material waste we churn out every day. I realised that we are, in fact, one of the culprits of the world’s pressing waste problem,” he explains. “And so we question ourselves, what alternatives do we have other than using the limited raw materials? And the answer is, we don’t.”

Driven in part by guilt, part by a sense of responsibility to rectify the situation, Javis decided to take the matter into his own hands. Joining Arthur, his then professor who shared the same frustrations, they founded Miniwiz to explore the potential of a circular practice in the industry, one that put discarded materials into use. “There’s often a misconception among the public that recycled materials are ugly or of low quality. Hence, Miniwiz strives to make trash sexy, to reappropriate them for other usages in people’s everyday lives,” says Javis.

And the duo has proven they don’t just talk the talk. Two years after its inception, Miniwiz debuted their first product HYmini. Designed with recycled plastic, paper and electronic waste, it was one of the first portable chargers that harnessed wind and solar power to generate electricity. HYmini was a runaway success, bringing the green startup its first batch of funding for the hundreds of inventive projects that have come since, all built with the aim of developing sustainable, high-performance alternatives to the finite raw materials – and with zero carbon footprint.

Still embracing the same vision, the company has now risen to worldwide prominence in the green tech and design field. Today, Miniwiz is run by a dedicated team of more than 40 engineers, designers and architects from across the world. With their innovative projects, such as the House of Trash in Milan, a contemporary 4300 sq.ft shared space concocted solely with local waste and a semi-transparent Nike Air Max shoe box made from cartons and plastic coffee lids, Miniwiz has sent a clear message that trash is just as viable as the virgin materials society has traditionally depended upon.

And, financially speaking, their business is lucrative. “We believe, to re-evaluate the role of trash in society, to push forth this trash-to-material circular concept, we have to prove that upcycled products themselves are desirable and profitable, that it is worthy for businesses to recycle and invest in upcycling,” says Javis. And they have, through providing their trash-repurposing technology and services to some of the world’s leading companies such as Coca-Cola and Starwood Hotels, Miniwiz generated an estimated annual revenue of over USD 100 million.

This impressive number is a testimony to Miniwiz’s closed-loop business model, one which seeks to achieve more with fewer resources. “We want to establish ourselves as the epitome of a scalable closed-loop business, to demonstrate the financial feasibility of our model, and eventually convince others to join us and rethink trash,” Javis elaborates. These days, they’re doing that by taking their message to the masses. In July, Miniwiz created an open-access trash database detailing research for the mechanical properties of waste that Miniwiz has collected over the course of its 13-year history. “We want to share our technology with all green innovators. Instead of us providing trash solutions to companies, we want businesses to also show real accountability for the trash they’ve created, and, eventually, make the closed-loop economy a reality in every day’s consumption.” It’s a plan that could be every bit as ambitious, innovative and game-changing as Miniwiz itself.

Related Articles

Interior Styling: The Secret to Dressing Up Your Home

7 Ways to Make Your Home Look Glamorous on A Budget

Architecture Collective Studiofour Brings Danish Concept Hygge to Melbourne Home